Imagine this: you’re ready for a day on the water, but your boat refuses to start. Frustrating, right? This guide tackles nine common boat starting problems, providing ten practical troubleshooting steps to get you back on the water quickly. We’ll cover everything from engine troubles and electrical system malfunctions to fuel system issues, offering clear explanations and step-by-step solutions to help you diagnose and fix the problem, regardless of your mechanical expertise.

We’ll delve into the intricacies of your boat’s engine, electrical system, and fuel system, providing detailed explanations of common failure points and practical solutions. Whether you’re a seasoned boater or a novice, this guide will empower you to confidently troubleshoot and resolve those pesky starting problems, ensuring smooth sailing ahead.

Engine Trouble

Boat engine failures can be frustrating and potentially dangerous. Understanding common causes and troubleshooting techniques is crucial for any boat owner. This section will cover several key areas to investigate when your boat’s engine refuses to start or fails during operation.

Common Causes of Engine Failure

Engine failure in boats stems from a variety of sources, often interconnected. Fuel system problems, electrical faults, and mechanical issues are the most prevalent culprits. A systematic approach to troubleshooting is essential to pinpoint the root cause efficiently. Ignoring seemingly minor issues can lead to more significant and costly repairs later.

Fuel System Inspection

Inspecting the fuel system involves checking the fuel lines, filter, and injectors for blockages or leaks. Leaks can be identified visually by checking for fuel stains or dampness along the fuel lines. Blockages often manifest as a lack of fuel flow to the engine. A clogged fuel filter will restrict fuel delivery, while faulty injectors will fail to atomize fuel properly, leading to poor combustion.

Fuel System Component Comparison

| Component | Function | Potential Failure Points | Troubleshooting Steps |

|---|---|---|---|

| Fuel Tank | Stores fuel | Leaks, corrosion, debris | Inspect for damage, check vent for blockage |

| Fuel Lines | Transport fuel from tank to engine | Leaks, cracks, kinks, blockages | Visually inspect for damage, check for fuel flow |

| Fuel Filter | Removes contaminants from fuel | Clogging, leaks | Inspect for debris, replace if necessary |

| Fuel Injectors | Atomize fuel for combustion | Clogging, leaks, low spray pattern | Check for leaks, consider professional cleaning or replacement |

Performing a Compression Test

A compression test measures the pressure inside each cylinder when the piston is at its top dead center. This test helps diagnose problems such as worn piston rings, damaged valves, or head gasket leaks. Low compression in one or more cylinders indicates a significant mechanical problem requiring professional attention.

- Disconnect the spark plugs.

- Install a compression gauge into the spark plug hole of the cylinder being tested.

- Have someone crank the engine over for several seconds.

- Record the pressure reading.

- Repeat for each cylinder.

- Compare readings to the manufacturer’s specifications. Significant discrepancies indicate a problem.

Diagnosing and Repairing Electrical Issues

Electrical problems can prevent engine starting or cause it to fail during operation. These issues can range from a dead battery to faulty wiring or a malfunctioning starter motor. Systematic troubleshooting is crucial.

- Check the battery voltage. A low voltage indicates a charging system problem or a weak battery.

- Inspect all wiring connections for corrosion or damage. Clean or repair as needed.

- Test the starter motor. A clicking sound may indicate a weak battery or a faulty starter solenoid.

- Check the ignition system, including the spark plugs and ignition coil. A weak spark will prevent proper combustion.

- Use a multimeter to test the voltage at various points in the starting circuit to identify breaks in the circuit.

Electrical System Problems

A boat’s electrical system is crucial for starting the engine. Malfunctions here can range from minor inconveniences to complete engine failure. Understanding common problems and their solutions is essential for any boat owner. This section will cover identifying and resolving electrical issues that prevent your boat from starting, comparing battery types, testing key components, and providing a systematic troubleshooting guide.

Common Electrical Problems and Solutions

Several electrical issues can hinder a boat’s ability to start. These often involve the battery, starter motor, wiring, or alternator. Identifying the specific problem is key to effective troubleshooting.

- Dead or Weak Battery: A low battery charge is the most frequent cause. Solution: Charge the battery or replace it if necessary. Regular battery maintenance, including checking the electrolyte levels and keeping the terminals clean, is preventative.

- Loose or Corroded Connections: Corrosion on battery terminals or loose wiring connections impede current flow. Solution: Clean terminals with a wire brush and baking soda solution, and tighten all connections.

- Faulty Starter Motor: A malfunctioning starter motor may fail to engage or turn the engine over. Solution: Test the starter motor (explained in a later section). Replacement may be needed.

- Bad Alternator: A faulty alternator won’t recharge the battery, leading to starting problems. Solution: Test the alternator (explained in a later section). Replacement is usually required for a malfunctioning alternator.

- Wiring Problems: Damaged or frayed wiring can interrupt the electrical circuit. Solution: Inspect all wiring for damage and repair or replace as needed. This often involves tracing the circuit from the battery to the starter motor.

Boat Battery Types and Applications

Choosing the right battery is vital for reliable boat operation. Different battery types offer varying performance characteristics and suit different applications.

- Flooded Lead-Acid (FLA): These are the most common and affordable type. They require regular maintenance, including checking electrolyte levels and adding distilled water as needed. Suitable for boats with moderate power demands.

- Absorbent Glass Mat (AGM): AGM batteries are sealed and maintenance-free. They are more resistant to vibration and offer better performance in extreme temperatures. Ideal for boats with higher power demands or those frequently used in harsh conditions.

- Gel Cell Batteries: Similar to AGM batteries, gel cell batteries are also sealed and maintenance-free. They are even more resistant to vibration and deep discharge. Suitable for boats with very high power demands or those used for extended periods without charging.

- Lithium-ion Batteries: These are the newest type and offer the highest energy density and longest lifespan. They are lighter than lead-acid batteries and charge faster. However, they are more expensive. Best suited for boats with very high power demands where weight and space are crucial.

Testing the Battery, Starter Motor, and Alternator

Testing these components is crucial for diagnosing electrical starting problems.

Battery Testing: Use a multimeter to check the battery’s voltage. A fully charged 12V battery should read approximately 12.6V. A lower reading indicates a low charge. A load test can further assess the battery’s ability to deliver current under load.

Starter Motor Testing: Testing the starter motor requires disconnecting it and applying power directly to its terminals. A functioning starter motor will spin vigorously. This test should be performed with caution and ideally by a qualified technician due to the high current involved.

Alternator Testing: An alternator test involves checking its output voltage while the engine is running. The voltage should be around 13.5-14.5V. A lower reading suggests a faulty alternator. A multimeter is essential for all these tests.

Troubleshooting Electrical Starting System Problems

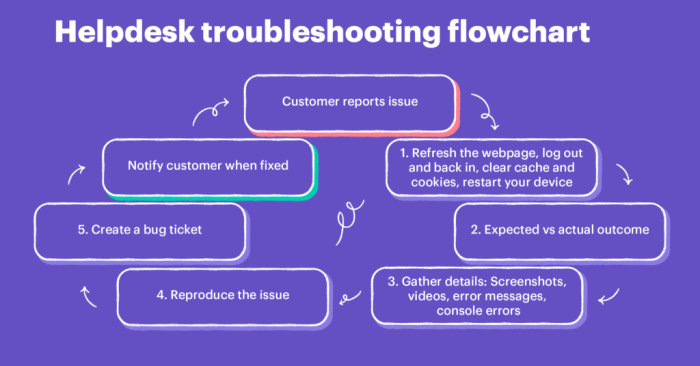

This flowchart guides you through systematic troubleshooting:

Flowchart:

(Imagine a flowchart here with boxes and arrows. The flowchart would start with “Boat won’t start,” branch to “Check battery voltage,” then to “Low voltage” or “Normal voltage,” etc., ultimately leading to solutions like “Charge battery,” “Replace battery,” “Check starter motor,” “Check alternator,” etc.)

Voltage Readings During Starting

| Component | Expected Voltage (V) – Engine Off | Expected Voltage (V) – Key On (Ignition) | Expected Voltage (V) – Cranking |

|---|---|---|---|

| Battery | 12.6 | 12.4 – 12.6 | 10 – 11 (dropping during cranking) |

| Battery Terminals (positive and negative) | 12.6 | 12.4 – 12.6 | 10 – 11 (dropping during cranking) |

| Starter Motor Terminals | 12.6 | 12.4 – 12.6 | 10 – 11 (dropping during cranking) |

| Alternator (Engine Running) | N/A | N/A | 13.5 – 14.5 |

Fuel System Issues

A properly functioning fuel system is crucial for a boat engine to start reliably. Neglecting fuel system maintenance can lead to frustrating breakdowns and potentially costly repairs. Understanding the common causes of fuel-related starting problems and implementing preventative measures is key to enjoying smooth sailing.

Proper Fuel Storage and Handling

Storing and handling fuel correctly significantly reduces the risk of contamination and degradation, preventing starting problems. Fuel should always be stored in approved containers, away from ignition sources, and in a cool, dry location. Avoid leaving fuel exposed to direct sunlight for extended periods, as this can accelerate deterioration. Regularly inspect fuel lines and connections for leaks or damage, replacing any components showing signs of wear. Using a fuel stabilizer, especially during periods of non-use, helps prevent the formation of gums and varnishes that can clog fuel filters and injectors.

Checking for and Removing Water Contamination

Water in the fuel tank is a common cause of engine starting problems. To check for water, carefully siphon a small amount of fuel from the lowest point of the tank using a clean container. Allow the fuel to settle; any water present will sink to the bottom. If water is detected, the entire tank should be drained and thoroughly cleaned. Water removal systems, such as water separators, can be installed to prevent water from reaching the engine. Using a fuel filter with a water separator is highly recommended to further protect the engine from water contamination. After draining and cleaning the tank, refill with fresh, clean fuel.

Potential Fuel-Related Starting Problems and Solutions

Several fuel-related issues can prevent a boat engine from starting.

- Clogged fuel filter: A clogged fuel filter restricts fuel flow to the engine. Solution: Replace the fuel filter.

- Bad fuel pump: A malfunctioning fuel pump fails to deliver sufficient fuel pressure. Solution: Inspect the fuel pump for damage or leaks; replace if necessary.

- Fuel tank vent blockage: A blocked vent prevents air from entering the tank, inhibiting fuel flow. Solution: Inspect and clear the vent line.

- Water in fuel: Water in the fuel can cause corrosion and prevent proper combustion. Solution: Drain and clean the fuel tank; install a water separator.

- Bad fuel: Old or contaminated fuel can cause starting problems. Solution: Drain and replace with fresh fuel; use a fuel stabilizer.

- Clogged fuel injectors: Clogged injectors prevent proper fuel atomization. Solution: Clean or replace the fuel injectors.

Preventing Fuel-Related Starting Problems

Following these practical tips will help prevent many fuel-related starting problems.

- Use only clean, fresh fuel.

- Regularly inspect and replace fuel filters.

- Store fuel properly in approved containers.

- Install a water separator in the fuel system.

- Use a fuel stabilizer, especially during periods of non-use.

- Regularly inspect fuel lines and connections for leaks.

Fuel Flow Diagram

Imagine a diagram showing the fuel flow from the fuel tank to the engine. The diagram would start with the fuel tank, showing the fuel pickup, which draws fuel from the tank. The fuel then travels through a fuel line to the fuel filter. The filter removes any debris or water from the fuel. After the filter, the fuel travels through another fuel line to the fuel pump, which pressurizes the fuel before sending it to the engine’s fuel injectors or carburetor. Potential points of failure include the fuel pickup (clogged or damaged), fuel lines (leaks or blockages), the fuel filter (clogged), and the fuel pump (malfunction). Finally, the fuel reaches the engine where it is used for combustion.

End of Discussion

Successfully navigating the complexities of boat engine starting requires a systematic approach. By understanding the interconnectedness of the engine, electrical, and fuel systems, and by methodically following the troubleshooting steps Artikeld in this guide, you’ll be well-equipped to diagnose and resolve a wide range of starting issues. Remember, preventative maintenance is key to avoiding future problems. Regular checks and proactive care will keep your boat running smoothly, ensuring many enjoyable hours on the water.