Maintaining your RV’s exhaust system is crucial for safe and enjoyable travel. Ignoring problems can lead to costly repairs and even dangerous situations. This guide tackles nine common exhaust issues, providing practical, budget-conscious solutions to keep your RV running smoothly. We’ll explore the root causes of these problems, detail their telltale symptoms, and offer step-by-step fixes using readily available materials. Learn how preventative maintenance can save you money and extend the life of your exhaust system, ensuring many happy miles on the road.

From identifying a leaky exhaust pipe to understanding the signs of a clogged system, we cover a wide range of issues. We’ll emphasize straightforward solutions, making repairs accessible even to those with limited mechanical experience. By following our advice, you can confidently address exhaust problems, keeping your RV running safely and efficiently.

Common RV Exhaust System Problems

Maintaining a properly functioning exhaust system in your RV is crucial for safety and comfort. A faulty system can lead to dangerous carbon monoxide buildup, reduced engine performance, and costly repairs. Understanding common problems and their causes allows for proactive maintenance and timely intervention. This section details six frequent issues, providing insights into their causes, symptoms, and initial assessment methods.

RV Exhaust System Problems: A Detailed Overview

| Problem | Cause | Symptoms | Initial Assessment |

|---|---|---|---|

| Leaks in the Exhaust System | Corrosion, cracks, loose connections, damaged clamps, or holes in the exhaust pipe. This is particularly common in older RVs exposed to the elements. | Loud exhaust noise, unusual smells (exhaust fumes) inside the RV, reduced engine performance, visible exhaust leaks (smoke or soot). A noticeable drop in engine power can also indicate a leak that’s restricting exhaust flow. | Visually inspect the entire exhaust system for any visible damage, cracks, or holes. Check all connections and clamps for tightness. Listen carefully for unusual noises while the engine is running. |

| Clogged Exhaust System | Buildup of soot, debris, or other obstructions within the exhaust pipe. This can be caused by extended use, poor fuel quality, or inadequate maintenance. | Reduced engine power, difficulty starting the engine, black smoke from the exhaust, unusual back pressure felt when the engine is running. The engine may also struggle to reach higher RPMs. | Check for any visible obstructions at the exhaust outlet. Listen for unusual gurgling or restricted airflow sounds. A pressure test may be necessary to determine the extent of the blockage. |

| Exhaust Pipe Corrosion | Exposure to moisture, road salt, and other corrosive elements. Aluminum exhaust systems are particularly susceptible to corrosion in humid climates. | Rust, pitting, or holes in the exhaust pipe. Exhaust leaks are a common symptom, leading to the issues described in the first problem. Discoloration and weakening of the pipe material are also indicators. | Thoroughly inspect the exhaust pipe for signs of rust, pitting, or other damage. Pay close attention to areas exposed to moisture and road spray. |

| Failed Exhaust Muffler | Rust, corrosion, or physical damage to the muffler. This component is particularly vulnerable to damage from road debris. | Loud and excessive exhaust noise, often accompanied by a rattling sound. The muffler may also show signs of rust or physical damage. | Visually inspect the muffler for any signs of damage, rust, or holes. Listen for any unusual noises while the engine is running. |

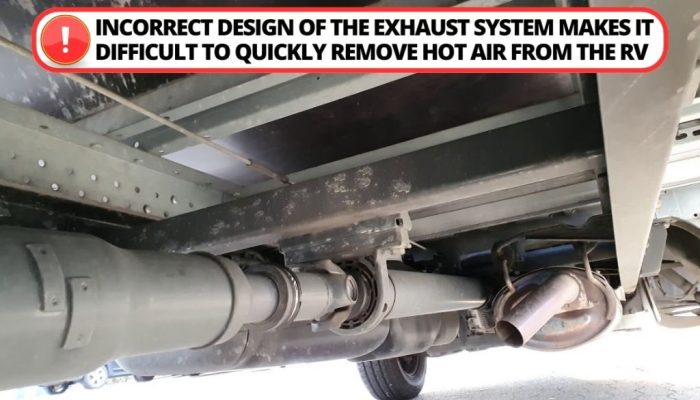

| Improper Exhaust Routing | Incorrect installation or modification of the exhaust system, potentially leading to exhaust fumes entering the RV. | Exhaust fumes inside the RV, headaches, nausea, or other symptoms of carbon monoxide poisoning. This is extremely dangerous and requires immediate attention. | Carefully examine the exhaust system’s routing to ensure it’s properly positioned and away from any potential entry points into the RV. |

| Loose or Damaged Exhaust Clamps | Vibration, age, or improper installation. Loose clamps can lead to leaks and exhaust noise. | Exhaust leaks, unusual exhaust noise, rattling sounds from the exhaust system. The leaks can be easily identified through visual inspection, often accompanied by the smell of exhaust fumes. | Inspect all exhaust clamps for tightness and damage. Tighten any loose clamps or replace damaged ones. |

Budget-Friendly Repair and Maintenance Solutions

Keeping your RV’s exhaust system in top shape doesn’t require a fortune. Many common problems can be addressed with simple, inexpensive repairs and regular maintenance. By investing a little time and effort, you can significantly extend the life of your exhaust system and avoid costly professional repairs down the line. This section details six cost-effective solutions, focusing on readily available materials and straightforward procedures.

Exhaust Pipe Patching with High-Temperature Tape

Minor exhaust leaks, often resulting from rust or small holes, can be temporarily sealed using high-temperature exhaust tape. This is a quick and easy fix for small problems, buying you time until a more permanent solution can be implemented.

Materials needed: High-temperature exhaust tape (available at most auto parts stores or online retailers like Amazon), wire brush, safety glasses, and work gloves. Sourcing these materials affordably can be done by comparing prices online and checking local auto parts stores for sales or discounts. Often, smaller, independent auto parts stores offer competitive pricing.

- Preparation: Clean the area around the hole thoroughly using a wire brush to remove any loose rust or debris. Safety precaution: Wear safety glasses to protect your eyes from flying debris.

- Application: Wrap the high-temperature tape tightly around the hole, ensuring complete coverage. Overlap each layer slightly for maximum effectiveness. Safety precaution: Wear work gloves to prevent skin irritation from the tape.

- Inspection: After application, allow the tape to cure according to the manufacturer’s instructions. Inspect the repair for any leaks.

Replacing a Damaged Exhaust Clamp

Loose or damaged exhaust clamps can lead to leaks and noise. Replacing them is a simple and inexpensive repair.

Materials needed: Replacement exhaust clamp (size should match your existing clamp; check the diameter before purchasing), wrench (size appropriate for the clamp), and work gloves. Affordable clamps can be found at most auto parts stores, and online marketplaces often offer competitive pricing, especially when buying in bulk.

- Removal: Carefully loosen and remove the damaged clamp using the appropriate wrench. Safety precaution: Wear work gloves to protect your hands and avoid burns from hot exhaust components. Allow the exhaust system to cool completely before working on it.

- Installation: Position the new clamp around the exhaust pipe connection and tighten securely with the wrench. Safety precaution: Ensure the clamp is properly aligned to avoid pinching the exhaust pipe.

- Inspection: Check for leaks after tightening the clamp.

Exhaust Pipe Repair with Aluminum Tape

For larger holes or more extensive damage, aluminum tape offers a stronger, more durable solution than exhaust tape. While not a permanent fix, it provides a more robust temporary repair.

Materials needed: High-temperature aluminum tape (available at auto parts stores and online), metal shears or a sharp knife, and safety glasses. This is generally more expensive than exhaust tape but offers greater durability for larger repairs. Look for sales and consider buying in bulk to reduce cost.

- Preparation: Clean the area around the hole, removing any loose rust or debris. Safety precaution: Wear safety glasses to protect your eyes.

- Cutting and Application: Cut a piece of aluminum tape slightly larger than the hole. Apply it firmly over the hole, pressing down to ensure good adhesion. Safety precaution: Use caution when using shears or a knife.

- Reinforcement (Optional): For added strength, apply additional layers of aluminum tape, overlapping each layer slightly.

Cleaning the Exhaust System

Buildup of soot and debris can restrict airflow and reduce efficiency. Regular cleaning can improve performance and prevent more serious problems.

Materials needed: Wire brush, shop vacuum, and safety glasses. These are commonly available items and are generally inexpensive.

- Preparation: Allow the exhaust system to cool completely. Safety precaution: Never attempt to clean a hot exhaust system.

- Cleaning: Use a wire brush to remove loose soot and debris from the exhaust pipe and muffler. Safety precaution: Wear safety glasses to protect your eyes.

- Vacuuming: Use a shop vacuum to remove any remaining debris.

Repairing a Loose Exhaust Manifold

A loose exhaust manifold can cause significant leaks and noise. Proper tightening is crucial.

Materials needed: Socket wrench set (size appropriate for your manifold bolts), penetrating oil (like PB Blaster), and work gloves. These are common tools for most mechanics, and purchasing them individually can be more expensive than purchasing a set.

- Preparation: Allow the exhaust manifold to cool completely. Apply penetrating oil to the manifold bolts to loosen them. Safety precaution: Wear work gloves and eye protection.

- Tightening: Carefully tighten the manifold bolts using the appropriate socket wrench. Safety precaution: Avoid over-tightening, which can strip the bolts or damage the manifold.

- Inspection: Check for leaks after tightening the bolts.

Replacing a Damaged Exhaust Pipe Section (Minor Damage)

For minor damage to a short section of exhaust pipe, replacement might be more cost-effective than a complete system overhaul.

Materials needed: Replacement exhaust pipe section (matching diameter and length), exhaust clamps, and the appropriate tools for cutting and installation. Sourcing a replacement section might require visiting a specialized RV parts supplier or a local muffler shop. They may be able to cut a section to the right size for a more affordable price.

- Removal: Carefully remove the damaged section of exhaust pipe, using the appropriate tools. Safety precaution: Wear gloves and eye protection. Allow the system to cool completely.

- Installation: Install the replacement section, securing it with new exhaust clamps. Safety precaution: Ensure proper alignment to prevent leaks and ensure the system is securely fastened.

- Inspection: Check for leaks after installation.

Preventing Future Exhaust System Issues

Proactive maintenance is key to extending the lifespan of your RV’s exhaust system and avoiding costly repairs down the road. Regular inspections and simple upkeep can significantly reduce the risk of breakdowns and ensure safe, efficient operation. By addressing potential problems before they escalate, you’ll save money and enjoy worry-free travels.

Preventative maintenance involves a combination of regular inspections, cleaning, and minor repairs. These practices not only extend the life of your exhaust system but also improve its efficiency, leading to better fuel economy and reduced emissions. The effectiveness of these techniques varies depending on factors such as climate, usage, and the quality of the initial installation, but consistent application always pays off. The long-term cost savings from preventative maintenance far outweigh the relatively small investment of time and resources required. A small amount of effort now can prevent significant expenses and inconvenience later.

Preventative Maintenance Schedule

A well-structured preventative maintenance schedule is crucial for keeping your RV’s exhaust system in top condition. The following schedule Artikels recommended tasks and their frequency, helping you stay ahead of potential problems. Remember to adjust the frequency based on your RV’s usage and environmental conditions. More frequent checks are advisable in harsh climates or with heavy use.

- Visual Inspection (Monthly): Check for any visible damage, such as cracks, rust, holes, or loose connections in the exhaust pipe, muffler, and tailpipe. Look for signs of soot buildup or excessive corrosion.

- Exhaust System Cleaning (Annually): Use a wire brush or compressed air to remove any accumulated debris or soot from the exhaust pipe and muffler. This improves airflow and prevents blockages.

- Clamp Inspection and Tightening (Annually): Check all clamps and fasteners along the exhaust system for tightness. Loose connections can lead to leaks and noise.

- Professional Inspection (Every 2-3 Years): Schedule a professional inspection by an RV mechanic to identify any potential issues that might not be visible during a routine check. A professional can assess the overall condition of the system and identify any hidden problems.

- Rust Prevention (Annually): Apply a rust-preventative coating, such as a high-temperature paint, to vulnerable areas of the exhaust system to protect against corrosion, especially in areas with high humidity or salt spray.

Comparison of Preventative Maintenance Techniques

Different preventative maintenance techniques offer varying levels of effectiveness in protecting your RV’s exhaust system. For instance, a simple visual inspection is a cost-effective way to catch minor problems early, while a professional inspection provides a more comprehensive assessment. Regular cleaning prevents blockages and improves efficiency, while rust prevention significantly extends the lifespan of the system in harsh environments. The most effective approach involves a combination of these techniques, tailored to your specific needs and circumstances. For example, a coastal RV owner should prioritize rust prevention, while someone in a dry climate might focus more on cleaning and regular inspections.

Closure

Addressing RV exhaust system problems proactively can prevent costly repairs down the line and ensure your safety. By understanding the common issues, their causes, and implementing both cost-effective repairs and preventative maintenance strategies, you can significantly extend the lifespan of your RV’s exhaust system. Remember, regular inspections and attention to detail are key to preventing major problems and maintaining a safe and reliable RV for years to come. Safe travels!